Cold resistant standards and test methods

Testing for cold resistance

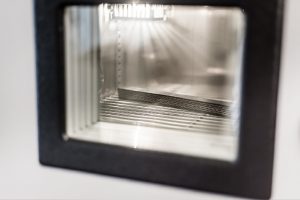

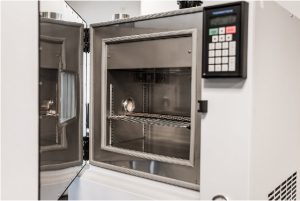

There are no current internationally recognised test methods for specifically determining a conveyor belt’s ability to function in extremely cold conditions. At Dunlop we carry out laboratory testing using a liquid nitrogen freezing cabinet to test samples of rubber belting at extreme low temperatures.

Belt samples are frozen using liquid nitrogen

The elastic modulus of the samples are first measured at an ambient temperature of 20°C. The samples are then placed inside the cabinet. The temperature in the cabinet is then gradually reduced by stages of 5°C. The elastic modulus is measured at each stage to determine when the decrease in flexibility of the rubber becomes too great, thereby identifying its lowest permissible ambient temperature.