Heat resistance

Heat resistance

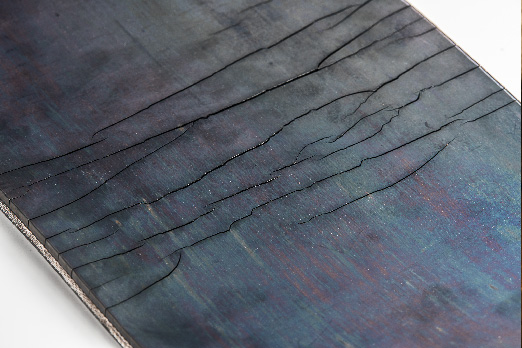

Of all the demands placed on conveyor belts, heat is usually the most unforgiving and damaging. High-temperature environments accelerate the ageing process, which causes the rubber to harden and crack. Heat also has a seriously harmful effect on the belt carcass itself because it damages the adhesion between the cover and the carcass and between the fabric plies contained within the carcass. This literally causes the belt to fall apart. This is commonly referred to as ‘de-lamination’. As rubber becomes harder and less elastic due to the exposure to heat the tensile strength and the elongation at break can fall by as much as 80%. This effectively destroys its operational strength and flexibility. At the same time, resistance to abrasion can decrease by as much as 40% or more. As the reference guide below shows, Dunlop heat resistant belts not only withstand heat extremely well, they also provide exceptionally long wear life compared to its rivals.

A QUICK REFERENCE GUIDE TO DUNLOP HEAT RESISTANT COVERS

UP TO 180°C

Dunlop Betahete is a high-performance heat and wear-resistant rubber compound designed to handle materials at continuous temperatures up to 160°C and peak temperatures of up to 180°C. Betahete consistently exceeds the requirements demanded by ISO 4195 Class 2 (T125). Belt covers that have a high resistance to heat traditionally have a lower resistance to wear. Dunlop Betahete is an exception to the rule because it has an outstanding level of abrasion resistance that even exceeds the DIN X international standards applicable to purely abrasion-resistant belts.

UP TO 400°C

Dunlop Deltahete is recommended for more extreme temperatures in demanding heavy-duty service conditions to convey high-temperature loads of abrasive materials. It is specifically designed to withstand a maximum continuous temperature of the conveyed material as high as 200°C and extreme peak temperatures as high as 400°C. Deltahete exceeds the highest requirements of Class 3 and is therefore effectively Class 4, although this category does not yet exist within the ISO 4195 classifications. Although exposure to heat usually causes a significant deterioration in wear resistance, ISO 4195 laboratory testing has proved that even when continually exposed to 150° heat for 7 days, Dunlop Deltahete still retains its original (pre-test) resistance to abrasion.

Dunlop BVGT is a multi-purpose heat resistant (up to 150°C continuous with peaks up to 170°C) combined with the highest level of oil resistance (ASTM ‘D’). BVGT has an abrasion resistance superior to DIN X and is also fire resistant (ISO 340).

Learn more about the applicable quality standards and test methods

What they say about the product

"The materials our conveyors transport are often subjected to high temperatures. Dunlop Deltahete belts allow a lifespan far superior to what we knew before. We are seeing real productivity gains"

Download technical bulletin

In this document you can find information about heat resistance.

Heat resistance belts

Superfort®

Fenner Dunlop Superfort ‘long life’ multi-ply conveyor belts have a long history of outstanding reliability and durability.

Ferroflex®

Fenner Dunlop Ferroflex has a tension layer composed of longitudinal steel cords through which power transmission is effected.

High Impact / Heavy-duty Belts

Trioflex®

Trioflex has been designed in line with the modern MPC-trend (minimum ply concept) and can be used very successfully for medium up to the heaviest service conditions, adverse loading conditions and coarse materials.