Ozone & UV resistance

Although not an actual cover grade in its own right, there is no question that ALL rubber conveyor belts need to be fully resistant to the damaging effects of ozone and ultraviolet light. This is because at low altitude ozone becomes a pollutant. Exposure increases the acidity of carbon black surfaces and causes reactions to take place within the molecular structure of the rubber. This has several consequences such as surface cracking and a marked decrease in the tensile strength of the rubber.

Ozone & UV exposure seriously damages the rubber

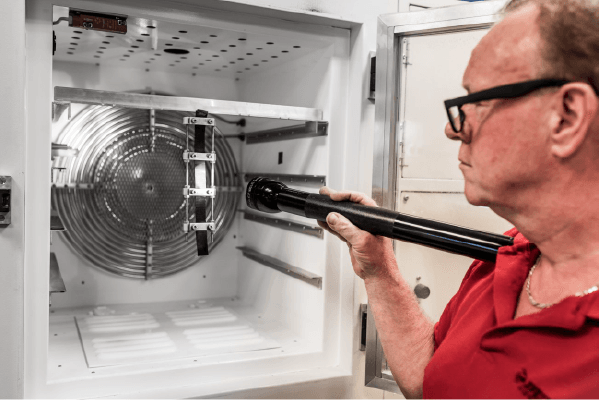

Likewise, ultraviolet light from sunlight and fluorescent lighting also accelerate deterioration because it produces photochemical reactions that promote the oxidation of the surface of the rubber resulting in a loss in mechanical strength. Here at Dunlop, ozone resistance testing has long been a mandatory part of our routine quality testing processes. Thanks to the special anti-ozonant additives used in our rubber compounds, all Dunlop belts are resistant to the effects of ozone and UV.

Here at Dunlop, EN/ISO 1431 ozone resistance testing has long been a mandatory part of our routine quality testing processes at Dunlop. Thanks to the special anti-ozonant additives used in our rubber compounds, all Dunlop belts have outstanding resistance against the effects of ozone and UV.

Learn more about the applicable quality standards and test methods

Download technical bulletin

In this link, you will find our latest technical bulletin about the effects of ozone of rubber.