Rip & Impact resistance

In conditions where heavy, sharp lump sizes and/or large drop heights are involved, having a carcass that has been specifically designed to dissipate impact and provide strong resistance against trapped objects that can rip through the belt is very important. For these situations, we strongly recommend either our UsFlex or Ultra X, which are specifically designed for the purpose. However, it is also essential to protect the carcass as much as possible with rubber covers that are best equipped to handle the impact, minimize rip & tear propagation and resist aggressive wear and the cutting and gouging caused by hard, sharp materials. For these kinds of demands, we recommend Dunlop cover grades RE, RS, and RES.

Dunlop Cover Quality |

DIN quality |

EN/ISO quality |

.

|

Dunlop RS |

W |

D |

Outstanding resistance against impact, wear, cutting and gouging. Average* abrasion resistance: 81mm³. Average* tear strength (N)/(Mpa): 110.4/13.8(ISO 34-2). |

Dunlop RE |

X |

H |

Excellent resistance to impact, abrasion, cutting, gouging resulting from heavy, sharp materials and high drop heights. Average* abrasion resistance: 99mm³. |

Dunlop RES |

W |

D |

Similar properties to RE but even greater wear resistance. RES has outstanding resistance against tear (rip) propagation. Average* abrasion resistance: 71mm³. |

* Dunlop actual performance averages presented above are achieved and recorded via our rigorous ongoing program of quality-testing.

Dunlop engineers have created a world-beating range of super-tough belts designed specifically for heavy-duty applications.

Click here to discover our High Impact / Heavy Duty Belts

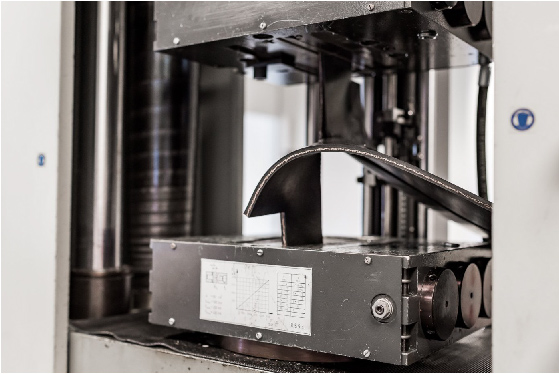

USING BREAKER PLIES TO INCREASE RIP RESISTANCE

For heavy-duty applications where ply belting is used we recommend the unique Dunlop UsFlex as the most effective solution. However, for steelcord belting, we recommend that breaker plies are used. These are embedded in the rubber covers during the manufacturing process, effectively creating a protective layer. The breaker plies are designed to significantly increase resistance against longitudinal ripping and perform two distinct functions. Firstly, they can help prevent the penetration of the belt by trapped objects and secondly they act as a barrier if something does actually penetrate between the steel cords and starts to rip the belt.

READ MORE ABOUT THE APPLICABLE QUALITY STANDARDS & TEST METHODS

What they say about the product

"I can honestly say that since we started using Dunlop belts we have not had a single problem with rip or tear, even when rocks have got into the hopper. They are so much stronger than anything I have ever come across"

Download technical bulletin

In this link you will find detailed information about our range of breakers and their properties.

Rip & Impact resistance belts

Dunloflex®

Dunloflex is designed for use with all types of bulk material transportation under light to medium-heavy service conditions in raw material, mining, stone, and earth handling and building industries.

Ferroflex®

Fenner Dunlop Ferroflex has a tension layer composed of longitudinal steel cords through which power transmission is effected.

High Impact / Heavy-duty Belts

Trioflex®

Trioflex has been designed in line with the modern MPC-trend (minimum ply concept) and can be used very successfully for medium up to the heaviest service conditions, adverse loading conditions and coarse materials.