Goodbye 2022, Hello 2023

As yet another turbulent year comes to a close, I look back with considerable pride at the way we have faced up to yet another wave of unprecedented challenges. Just when we thought that we had the damaging effects of the Covid 19 pandemic under control, the invasion of Ukraine by Russia in March turned the world upside down yet again. If anything, the problems created by the conflict were even worse than those caused by the pandemic. Russia was a big market for us so the embargo placed on exports stopped millions of euros of already-made orders from leaving the factory. However, losing that market was only the beginning.

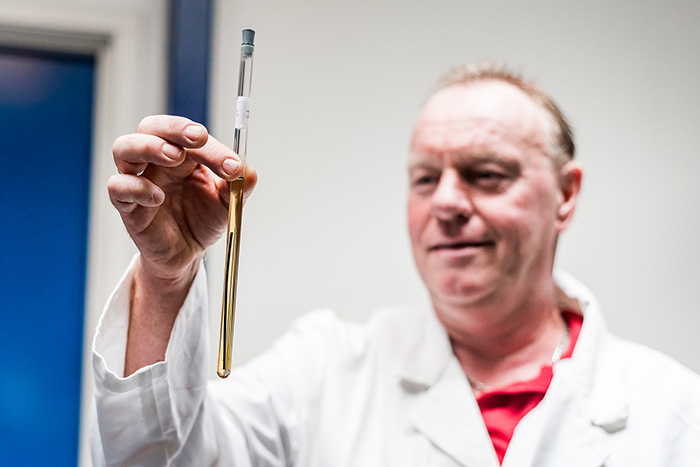

Russia was also the source of a third of the market for European manufacturers of carbon black, which is one of the most important ingredients of our rubber compounds. Because we only use premium grade we had to find alternative suppliers who could meet the quality as well as the volume demands. Unlike our competitors in South East Asia, we are subject to REACH regulation and EU regulations concerning Persistent Organic Pollutants. As with all of the raw materials we buy, we have to make 100% sure that what we are buying and using is safe for humans and the environment.

We have to be sure that all alternative ingredients are 100% safe

We have to be sure that all alternative ingredients are 100% safe

A unique advantage we have as an organization is what is referred to as ‘creation to destination’ because we do just about everything ourselves in-house. That is our ‘winning formula’ for the production of consistently top-quality products. A great example of this lies with our laboratory technicians, rubber compounders, and production staff who have been amazing in the way they have responded to the challenge. Alternative materials have to be rapidly evaluated technically and implemented in production to ensure that the quality of the finished product remains exactly the same as before.

The shortages and ongoing supply chain problems have resulted in huge increases in the prices of raw materials. The astronomical increases in the cost of energy were equally dramatic. Regrettably, it has been necessary to increase our prices to reflect those increases. Under the circumstances, from a sales perspective, 2022 was a remarkably good year. We particularly appreciate the continued support from our growing network of approved service partners, agents, and representatives. That support was very evident during the hugely successful BAUMA exhibition in Munich and the SIM tradeshow in Marseille. No other manufacturer has such a strong support network and it is something that we really appreciate and makes us very proud.

Another source of great satisfaction throughout the year was seeing how our marketing efforts have meant that we continue to have the highest profile of any conveyor belt manufacturer in the market by a considerable margin. Although our marketing activity is very important, what is even more important to our customers is having access to the professional guidance and support provided by our first-class team of sales managers, sales support personnel, and application engineers. It is the biggest team of its kind in the industry and continues to be one of the many good things that set us apart from the rest.

With so many challenges to deal with, it would be easy to put our environmental efforts on hold but that is not an option. We have been taking our responsibility for environmental impact very seriously for a very long time and we have no intention of stopping now. We remain determined to continue leading our industry by example. 2023 will therefore see an even greater emphasis on our part in three key areas; product life cycle, the environmental impact of our products, and our production processes.

Throughout 2022, we invested heavily in improving production efficiency. During the first quarter, we completely refurbished Press number 9, which is the biggest press we have. Virtually every part was renewed except for the steel framework and we are now able to make belts up to 2200mm wide. During the summer holidays, we replaced our biggest mixer with a new mixer from a well-known German supplier. Plans for further improvements are already in place for 2023. New mills have been bought for mixer 1 and calendar 2. Next to this, a brand new ‘batch off’ for mixer 1 has also been ordered. We hope that installation will be possible in 2023 but supply issues may delay that until the following year. As our chief operating officer, Kerstin de Haan, will be announcing in widely published industry magazine articles early in the New Year, we are determined to achieve sustainable growth now and in the future.

My sincere thanks to everyone who has played a part in what has been another great year for our company. There are a lot of very positive things that are happening in our company so I very much look forward to even more success in 2023.

Andries Smilda

What they say about the product

""With so many challenges to deal with, it would be easy to put our environmental efforts on hold but that is not an option.""